Pushing to Close: Top Considerations for Door Closers

A Critical Tool for Safety, Privacy, Code Compliance

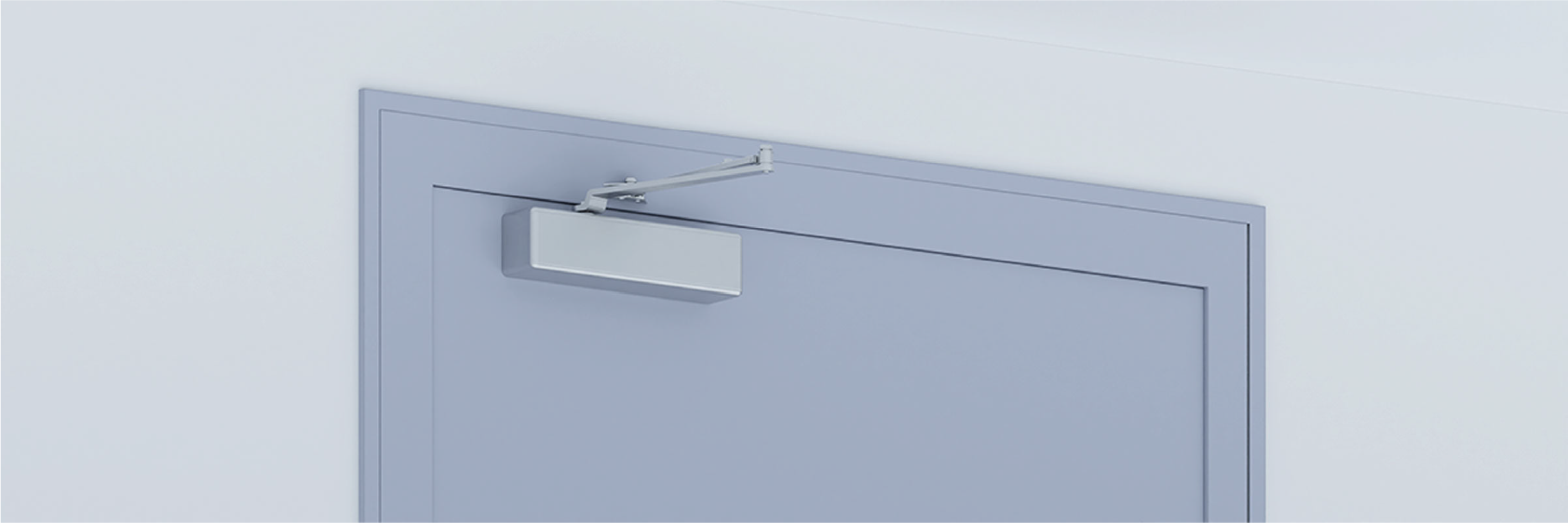

Consider the last time you stayed in a hotel. As you left your room, the door to that room almost certainly closed with force and determination. It was not necessary for you to pull it shut yourself. Such doors are engineered to be self-closing because they are heavy, fire-rated doors primed for the safety and security of the hotel guests. This enables the property to remain compliant with all applicable fire and building codes.

Without a door closer, doors would constantly swing open, potentially damaging the door, the door frame, or even people. No matter the building – a hotel, an office high rise, a medical complex, or a manufacturing facility – architects, specifiers, and building owners must ensure that all doors specified for that property are up to code and meet the desired accessibility of the door and the building.

How do you choose the right door closer for a door – on the outside of the property, for a stairwell, as an emergency exit, or as a way to gain access to a certain room? To make such selections, specifiers must ask a series of questions:

- Does the door closer need to meet specific fire safety regulations or building codes?

- Will it be used in high-traffic areas or in more controlled environments?

- What are the dimensions and weight of the door?

- Does the door closer need to offer adjustable closing speeds?

- Is the door susceptible to outside elements such as wind, rain, and snow?

Today’s door closers have evolved into sophisticated pieces of hardware. To assure convenience, privacy, efficiency, and safety, those automatic door closers must align with the contemporary design requirements in today’s commercial construction paradigm.

Up to Code

Installing door closers is key to ensuring compliance with local fire codes. Regulations mandate the installation of closers on every fire-rated door. Fire-rated doors are made with materials that are resistant to fire and heat (steel or fire-rated wood) and are equipped with fire-resistant seals around the edges to prevent the passage of flames and smoke.

When a fire occurs, fire-rated doors equipped with closers automatically close, limiting the fire's ability to move freely throughout a building. By doing so, fire doors equipped with closers can mitigate property damage resulting from fires and help save lives.

Door closers are also imperative for meeting the standards outlined in the American with Disabilities Act (ADA), which ensures a building is accessible for all individuals. For instance, for those with disabilities or mobility restrictions to get through a door, the closer needs to be slow enough to prevent the door from slamming into the individual. The ADA requires that any door with a closer take at least five seconds for the door to latch shut. The ADA also sets requirements for opening force, clearance, and swing distance.

Selection Criteria: Right Size, Right Speed

The American National Standards Institute (ANSI) rates door closers for performance and durability. ANSI’s grading system is based on the cycles of operation a door can withstand in testing. A door cycle is measured by the door being pushed fully open, and then fully closed. Where the door is located – and how it is going to be used – dictates the type of door closer to be considered:

- Grade 1: Highest grade, best used for heavier, wider doors that handle high traffic, such as entry doors. Tested for two-million cycles.

- Grade 2: Medium duty. Tested for one-million cycles.

- Grade 3: Low grade, light duty for interior commercial doors. Tested for 500,000 cycles.

The size and weight of a door are also key indicators for selecting the proper door closer. Is it an inner door or outer door? Does it open inside or outside? If a door closer is not appropriately matched to the weight, size, and use of the door, that door will struggle to close properly and provide adequate control. The speed and control of door closers are also impacted by weight and size. For instance, a heavier, larger door will require a slower closing speed to ensure the door does not slam shut without control, which can cause additional damage to the door. Depending on the location of the door, the closer may also need to perform in certain environmental conditions dictated by temperature, moisture, and wind and air pressure.

Spring Forward, Fall Back

When determining the size of a door closer, specifiers must consider the size or strength of the spring inside, not the size of the door closer body. The spring creates the opening and closing force of the door. Such springs are built in various power sizes ranging from size 1 (smallest) through size 6 (largest).

Adjustable door closers allow for customization of closing speed, closing force, and other parameters, ensuring the door will deliver optimal performance over the long haul. Installers can easily adjust the closer to achieve the desired closing speed and force, while maintenance personnel can adjust over time to account for wear and tear or changes in usage patterns.

Take the case of the 700 Series door closer by Tell Manufacturing. The 700 series is a grade 1, heavy-duty cast aluminum surface applied closer, designed for commercial applications. The closer is adjustable for standard door applications and complies with fire ratings of up to three hours.

Doors Closed

Door closers certainly do not receive the same level of attention as the architectural or structural elements of any building. Oftentimes, their significance becomes apparent only after issues arise, such as when a door consistently slams shut, there is difficulty in opening the door, or a door is found to be noncompliant with building codes.

When considering the lifecycle of that building, it is critical for specifiers to know and understand the intricacies of selecting the right door closers for all the structure’s doors.

Making the optimal choices translates into long-term accessibility, security, and safety for everyone who enters and exits.